Columbus Egg Tester

A lab-scale device for non-destructive quality measurement of an egg

Columbus is the combination of the Acoustic Egg Tester (AET) and additional volume and shape parameters.

IMPORTANT NOTICE: we are currently developing a new version of Columbus - no new orders can be placed. The new system is expected to be available by Q4 2018.

ABOUT

Columbus is the combination of the Acoustic Egg Tester (AET), originally developed by the Egg Quality & Incubation Research Group of the University of Leuven (Belgium), and new features. As specialist in test & measurement equipment with focus on agriculture & Food industry, Octinion was chosen to further develop and commercialise the AET by the University of Leuven.

Features

Columbus combines many measurements:

- Measurement of shell strength (dynamical stiffness Kdyn)

- Automatic crack detection

- Egg weight

- Egg volume, shape and color (based on a vision sensor)

We have spent a lot of attention to improve the usability of the device. Main highlights are:

- Integration with your current IT system through a serial or Ethernet protocol

- Possibility to integrate with our cloud-based software to gather all your data

- Stand-alone device which no longer needs a computer to operate it

Why use Columbus?

- Speed: efficient way to measure multiple parameters of the egg

- Easy to use: all your data can be directly put in the right place on a network location, or communicated to another system. No other computers required to operate the device.

History

The vibrational excitation with an elastic hammer was developed in collaboration with MOBA BV (Barneveld, The Netherlands) and protected under the European patent EP 1 238 582 A2 and the US patent 6,722,201,B2. Up to today Columbus is still constructed and sold under this patent. The PhD-thesis of P. Coucke (1998) “Assessment of some physical egg quality parameters based on vibration analysis.” presented the first design of Columbus and the analysis of the vibrational response of a chicken egg after impact. The first application of the AET was Crack Detection and later a formula containing the vibrational response information was developed to calculate a new Shell Strength Parameter (Dynamical Stiffness Kdyn).

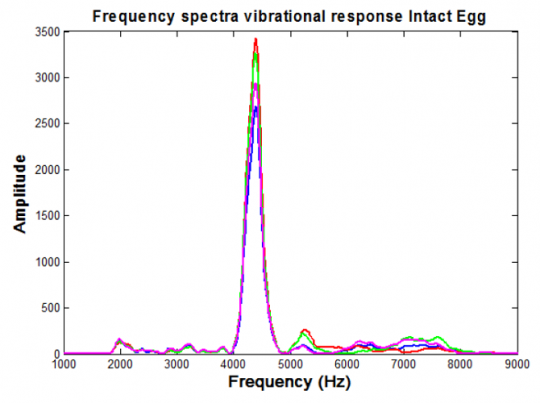

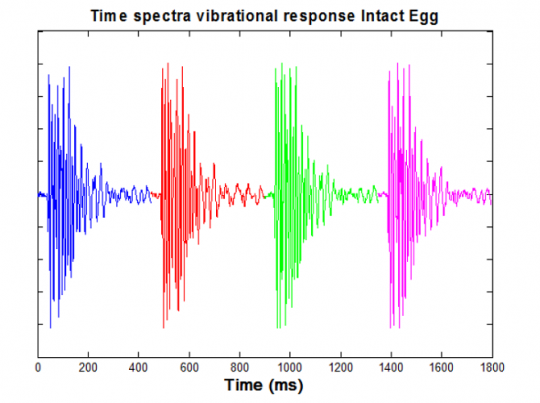

Acoustic Resonance analysis

Acoustic resonance analysis is a valuable technique used to study the vibrational behavior of all kind of products. Coucke (1998) was the first to apply this technique on eggs. The basic idea behind the technique is that the egg is excited by a impulse excitation, i.e. the impact of a small hammer on the shell, and the resulting vibration of the shell is recorded using a small microphone. The frequency spectrum of the vibration is calculated from this time signal. Finally, the resonant frequencies of the different vibrational modes can be estimated from the achieved frequency spectrum. The shell strength of eggs was derived from the resonant frequency of the first spherical mode (S20) of the egg and its mass. Colombus is of laboratory scale and consists of two rolls to support the egg and to rotate it around it’s longitudinal axis, a hammer made of a light rod to tap the eggs, and a microphone to record the resulting egg vibration.

In the figure next to this paragraphe an example is given of extracted frequency spectra of an intact egg. This egg shows an average resonant frequency of about 4300 Hz.

Legacy support

We do not support the hardware or software of the old AETs. We try however to help each customer, so contact us if you have an issue. There is also an option to upgrade the electronics of the old AET to the new version of the electronics.

We are always interested to hear from you about features you would like to see in the next generation of Columbus. Do not hesitate to contact us!

VERSIONS

BASIC

Automatic crack detection

When combined with an off-line weight measurement, you can also determine Kdyn

PLUS

Columbus basic features

Integrated weighing system with automatic calculation of Kdyn

VISION

Columbus basic and plus features

Vision sensor that determines egg volume, shape and color

Most popular